🔔From Engineer to Branded Customized Customer. Quality Parts. Fast. Easy. Affordable.g

📧

kyrie@premfixer.com

High-Precision Custom 3D Printing Services From China

Specializing in big size aluminum, titanium, and stainless steel for prototypes and bulk orders.

- Fast Turnaround From 3 – 7 Days

- Competitive Price 30% Cost Save

- Precision Metal & Plastic 3D Printing For Large Parts

We solemnly guarantee

: All uploads files are safe and confidentia

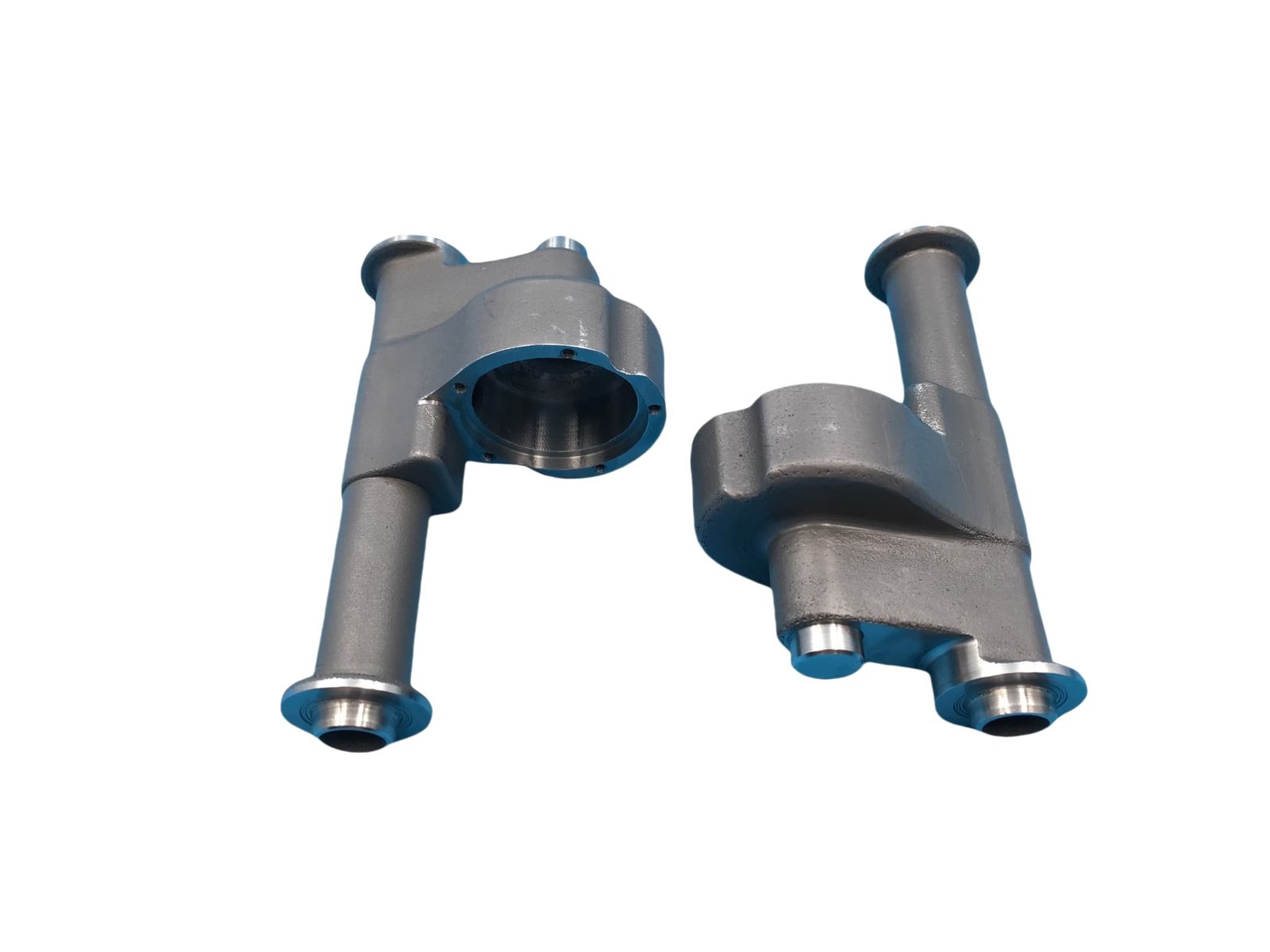

What We Good at CNC Machining Processes

At PremFixer, we provide a comprehensive range of CNC machining services, including CNC milling, CNC turning, drilling, tapping, and wire EDM. Our ISO 9001 certified production process, paired with cutting-edge CNC technology and years of industry expertise, guarantees that your custom parts are produced accurately and efficiently – right the first time, every time.

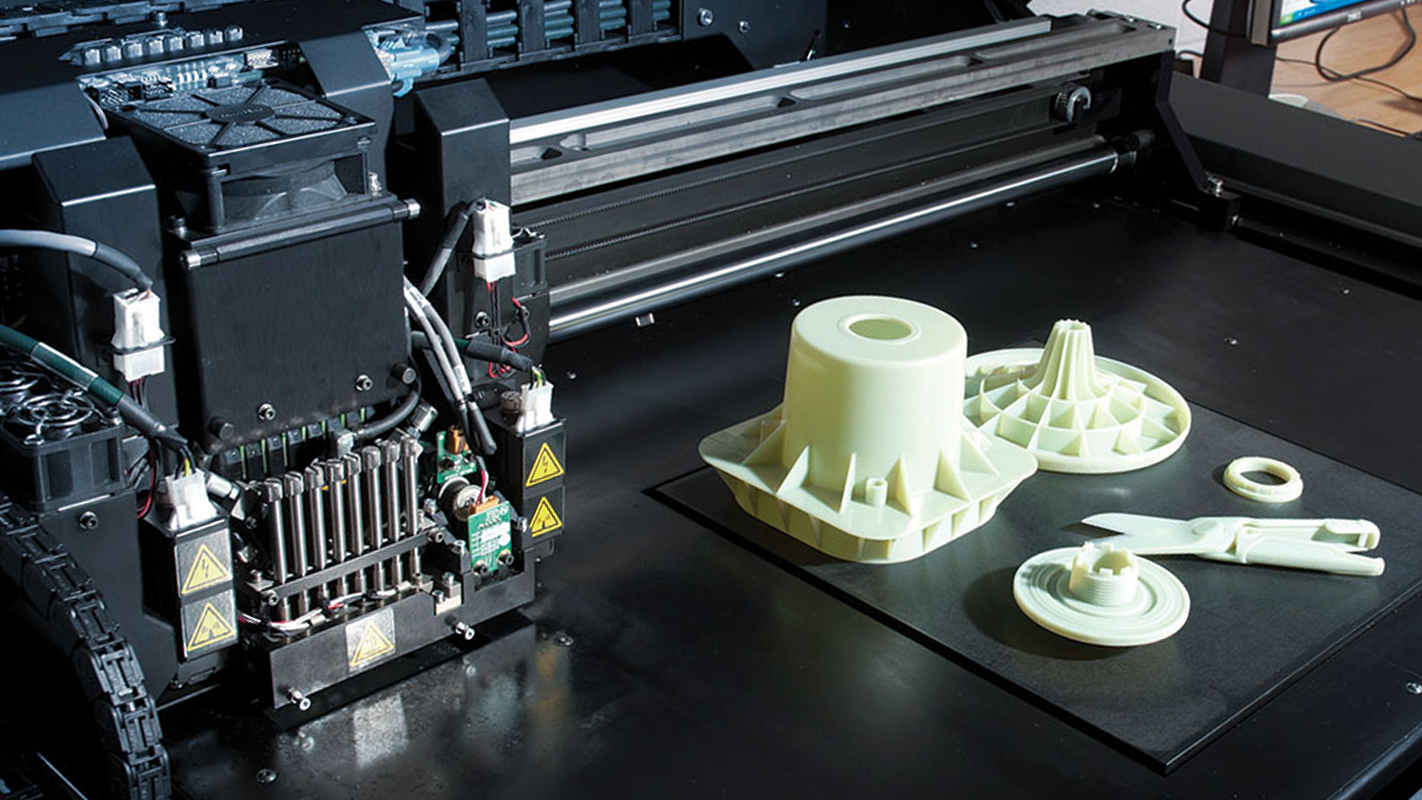

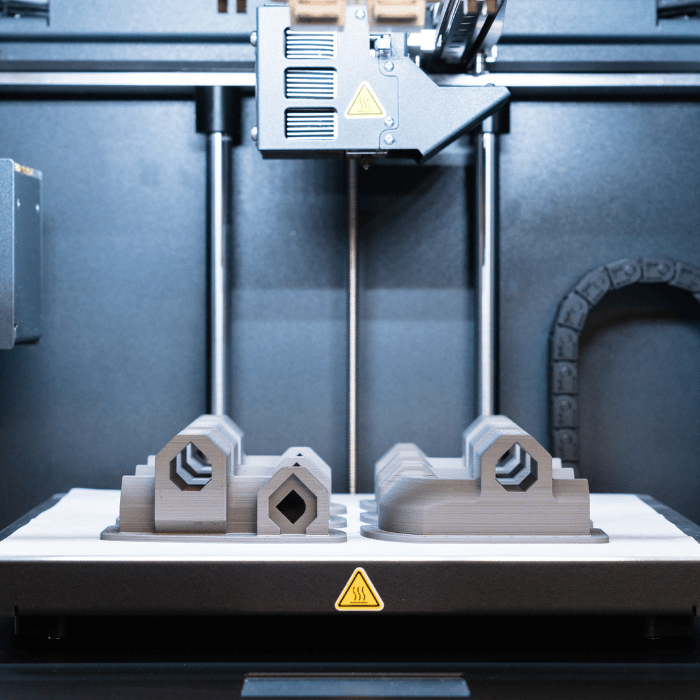

3D Plastic Printing Services

Plastic 3D printing service often referred to as additive manufacturing, involves creating three-dimensional objects by depositing plastic material layer by layer based on a digital model.

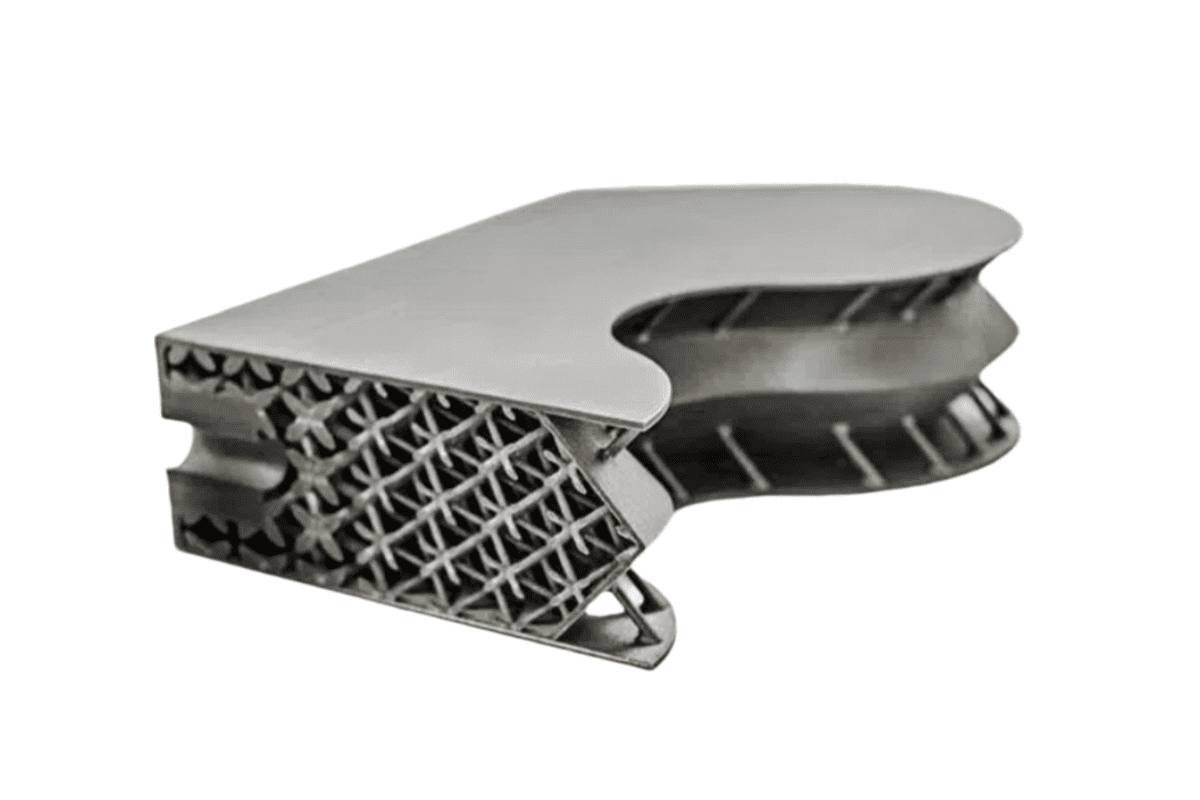

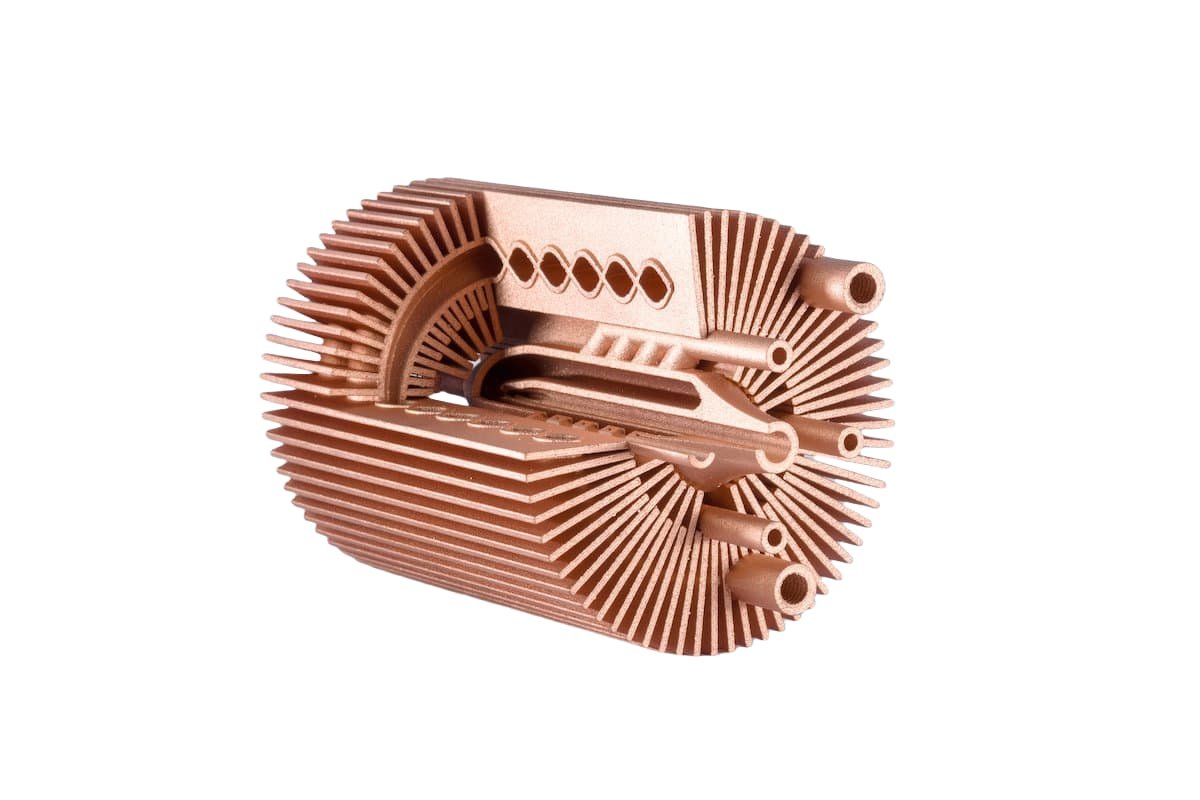

3D Metal Printing Services

Metal 3D printing is an advanced manufacturing process that builds three-dimensional metal parts by fusing or melting metal powders layer by layer according to a digital design.

Excellent Custom 3D printing Parts We Made

Metal & Plastic 3D Printing Materials We Offer

“Choosing between metal vs. plastic 3D printing depends on your project’s mechanical requirements. Plastic 3D printing services offer unmatched versatility for lightweight prototypes and low-stress functional parts. Conversely, our professional metal 3D printing service utilizes sintering technology to create complex, high-strength metal parts that traditional CNC machining cannot achieve. From biocompatible medical implants to heat-resistant automotive housings, PremFixer delivers precision additive manufacturing for every industry.”

Common metal and plastic 3D printing materials used by PremFixer include the following.

Lead Time: < 10 days

Tolerances: ±0.2mm (±0.007)

Max part size: 800 x 800 x 550 cm

Lead Time: < 10 days

Tolerances: ±0.2mm (±0.007)

Max part size: 800 x 800 x 550 cm

Lead Time: < 10 days

Tolerances: ±0.2mm (±0.007)

Max part size: 800 x 800 x 550 cm

Lead Time: < 10 days

Tolerances: ±0.2mm (±0.007)

Max part size: 800 x 800 x 550 cm

Lead Time: < 10 days

Tolerances: ±0.2mm (±0.007)

Max part size: 800 x 800 x 550 cm

What Factors Should Be Considered When Choosing A Metal or A Plastic for 3D printing?

| Consideration Factor | Description & Industrial Application |

|---|---|

| Mechanical Performance | Evaluate critical specs such as tensile strength, impact resistance, and fatigue life to ensure structural integrity for heavy-duty industrial components. |

| Thermal Stability | Analyze Heat Deflection Temperature (HDT) and thermal expansion rates, essential for parts in automotive engines or aerospace environments. |

| Chemical & Corrosion Resistance | Determine material compatibility with oils, solvents, and fuels. Crucial for medical-grade and marine-ready components. |

| Technology Compatibility | Match materials with specific 3D processes like SLM/DMLS for metal alloys or SLA/FDM for high-performance polymers. |

| Precision & Surface Finish | Assessment of surface roughness (Ra) and detail resolution, factoring in post-processing like CNC bead blasting or polishing. |

| Production Cost Optimization | Balancing raw material expense with printing efficiency to achieve the best ROI for custom prototypes or low-volume manufacturing. |

| Scalability & Volume | Choosing materials that allow for seamless transition from rapid prototyping to batch production without compromising quality. |

| Regulatory Compliance | Ensuring materials meet global industrial standards including ISO 9001, RoHS, REACH, or FDA requirements for safety. |

| Turnaround Time | Optimization of material choice to ensure rapid lead times and meet critical project deadlines in fast-paced markets. |

Main printing technologies for both metal and plastic 3D printing

At PremFixer, we leverage advanced Additive Manufacturing technologies to bridge the gap between complex designs and functional reality. Our Metal 3D Printing (SLM) excels in consolidating multi-part assemblies into single, high-density components with superior structural integrity for mission-critical applications. For versatile polymer solutions, our Plastic 3D Printing (SLA & SLS) services range from cost-effective rapid prototyping to high-resolution, intricate models with exceptional surface finish. Understanding the unique strengths of each modality is key to optimizing your production—explore our specialized technologies below to find the perfect fit for your engineering requirements.

| Technology | Technical Process | Industrial Materials | Strategic Benefits & Applications |

|---|---|---|---|

| Selective Laser Melting (SLM) | A high-energy fiber laser fuses spherical metal powder layer by layer. This Powder Bed Fusion process occurs in an inert argon environment to ensure 99.9% part density. | Stainless Steel (316L/17-4PH), Aluminum (AlSi10Mg), Titanium (Ti6Al4V), Inconel, and Tool Steel. |

Benefits: Superior structural integrity, high thermal conductivity, and fully functional metal components. Applications: Aerospace turbine blades, medical implants, and high-pressure manifolds. |

| Stereolithography (SLA) | A precision UV laser initiates photopolymerization, curing liquid resin into solid layers. Ideal for micron-level detail and ultra-smooth surfaces. | Engineering Resins (Tough, Flexible, Clear, High-Temp) and Biocompatible resins. |

Benefits: Unmatched surface finish (Ra < 1.6μm) and dimensional accuracy for complex master patterns. Applications: Investment casting patterns, dental surgical guides, and high-detail aesthetic prototypes. |

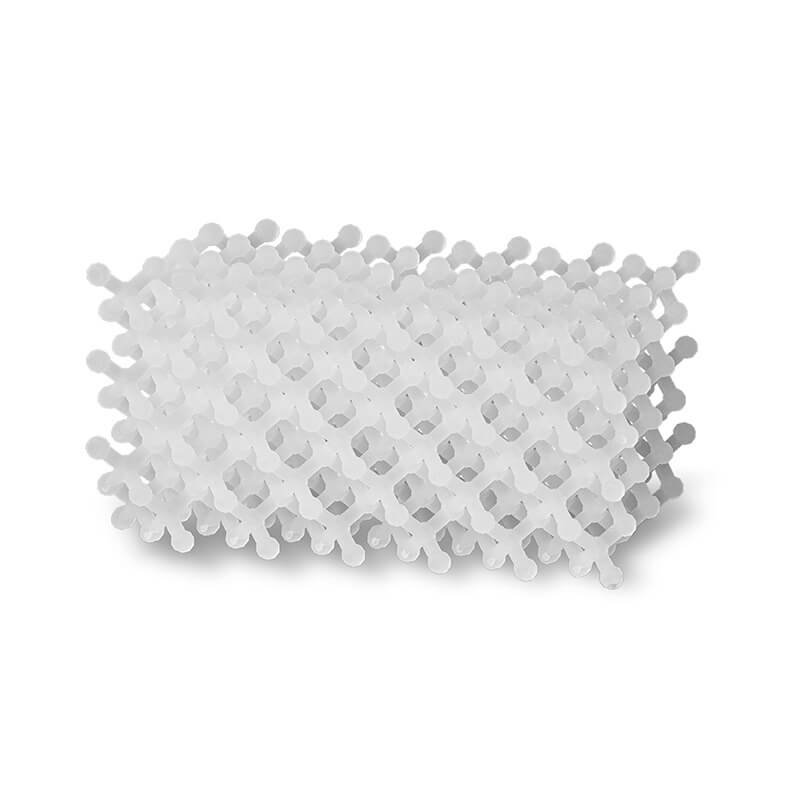

| Selective Laser Sintering (SLS) | A CO2 laser sinters thermoplastic powder. The self-supporting powder bed enables complex organic geometries without the need for manual support removal. | Nylon (PA11/PA12), Glass-filled Polyamides, and TPU (Flexible). |

Benefits: Isotropic mechanical properties, highly durable for functional testing, and batch production efficiency. Applications: Custom air ducts, wearable devices, and lightweight robotic grippers. |

PremFixer 3D Printing Capabilities

| Key Specifications | Metal (SLM) | Resin (SLA) | Nylon (SLS) |

|---|---|---|---|

| Structural Wall Thickness | Min. 0.8 mm | 0.6 mm (unsupported) / 0.4 mm (supported) | 0.7 mm (PA12) to 2.0 mm (Carbon-filled) |

| Layer Resolution | 30 – 50 μm | 25 μm – 100 μm | 100 – 120 μm |

| Industrial Build Envelope | Up to 400 x 400 x 350 mm | Up to 800 x 800 x 550 mm | Up to 400 x 400 x 350 mm |

| Dimensional Tolerance | ±0.2 mm (±0.25% for >100 mm) | ±0.1 mm (±0.15% for >100 mm) | ±0.3 mm (±0.35% for >100 mm) |

| Rapid Turnaround | 5 Business Days | 3 Business Days | 5 Business Days |

How To Work With Us

In order to saving the time and cost for our customer, we simply the working process, from the prototypes to custom parts deliveried fast only with 4 simple steps.

Send Us Design

Click any quote button on our website, fill in your requirements and upload the drawings.

Quote Analysis

Our engineers will analyze how to improve the parts and then provide you with the best prices.

Order Confirmed

After you confirm the quote, samples will be sent for approval, then bulk will be made.

Get your Goods

Custom precision parts undergo our QC inspection with flexible shipping via sea, air, or rail.

Get Your Custom 3D Printed Prototypes Today!

China-Based Manufacturer: Fasteners & Precision Custom Parts

“From Concept to Mass Production, PremFixer is committed to delivering ISO-certified quality and rapid turnaround on every order. Whether you require low-volume manufacturing, custom rapid prototyping, or high-precision CNC components for critical applications, our expert engineering team is ready to execute your design.”

Contact us today for a free quote or to discuss your project. Let’s work together to make your custom surface finishing precise, durable, and cost-effective.