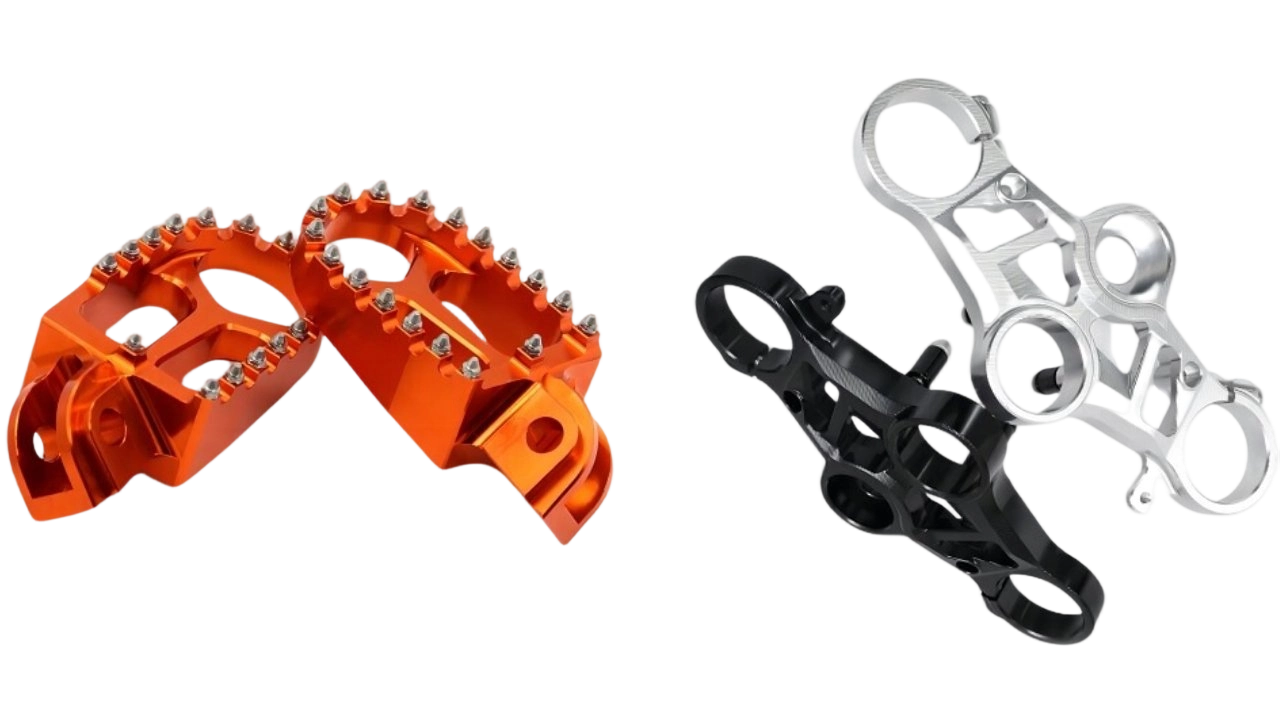

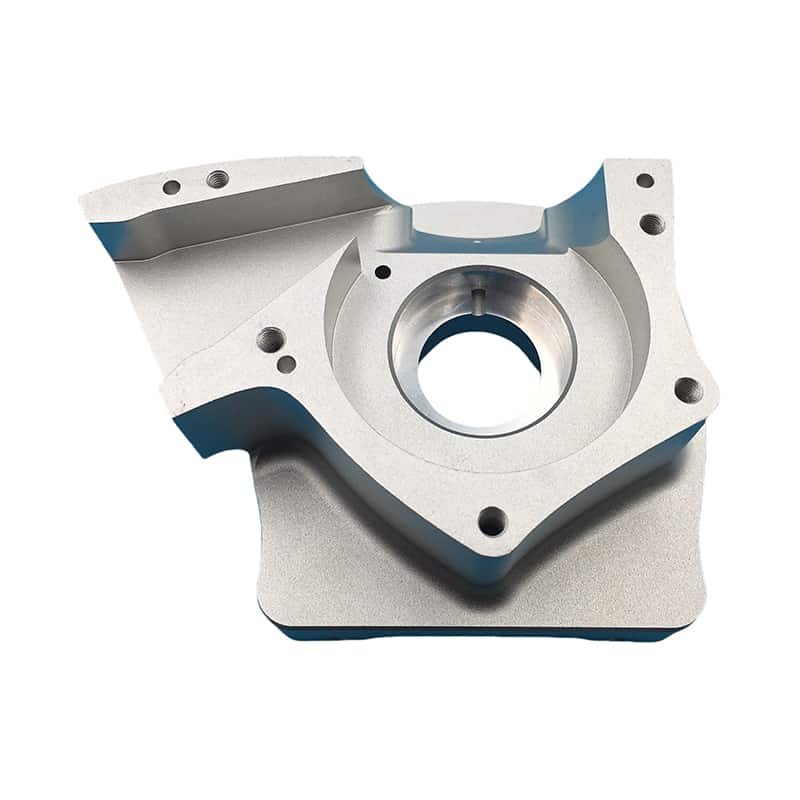

Metal CNC Machining

PremFixer delivers precision metal machining services, specializing in high-quality components with tight tolerances and complex geometries.

- Material Certificates

- Save 30% vs. Local Suppliers

- Fast Turnaround

- 15+ Years Experience

We solemnly guarantee

: All uploads files are safe and confidentia