🔔From Engineer to Branded Customized Customer. Quality Parts. Fast. Easy. Affordable.g

📧

kyrie@premfixer.com

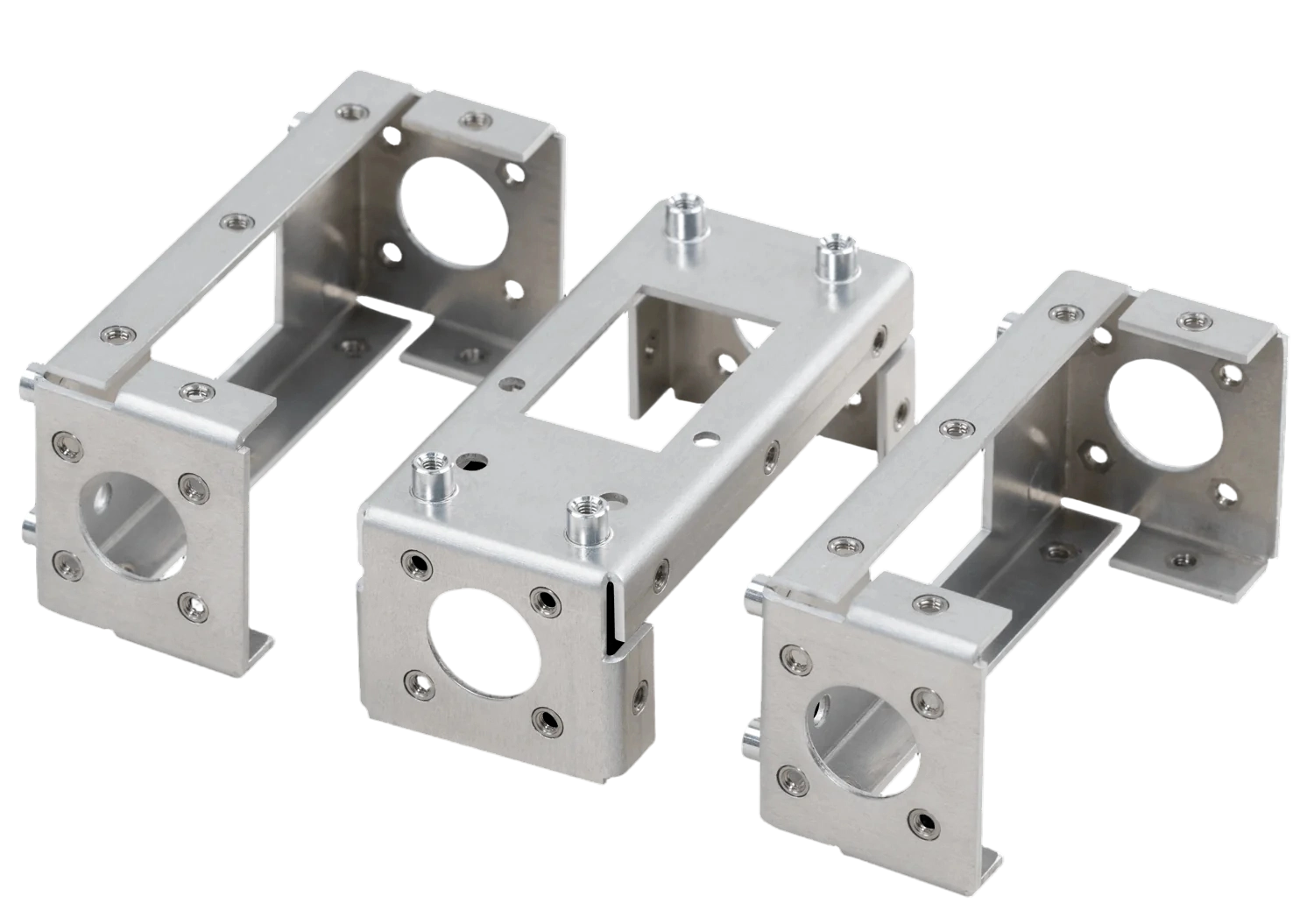

Custom Sheet Metal Fabrication Service

PremFixer provides precision custom sheet metal fabrication, specializing in high-quality parts with tight tolerances and complex geometries for industrial-grade applications.

- No MOQ!

- Fast Turnaround

- Competitive Price 30% Cost Save

- 15+ Years Design & Export Experience

We solemnly guarantee

: All uploads files are safe and confidentia

Precision Sheet Metal Fabrication Shop | Custom Metal Parts

Are you in need of a reliable, quick-turn supplier for custom sheet metal parts?

Looking for a reliable, quick-turn supplier for your custom sheet metal projects? PremFixer provides expert precision sheet metal fabrication services, specializing in high-quality parts with tight tolerances and complex geometries. From CNC laser cutting to precision bending and welding, our 15+ years of industry experience ensures your project requirements are met with uncompromising quality and competitive pricing.

Our sheet metal custom fabrication Capacity

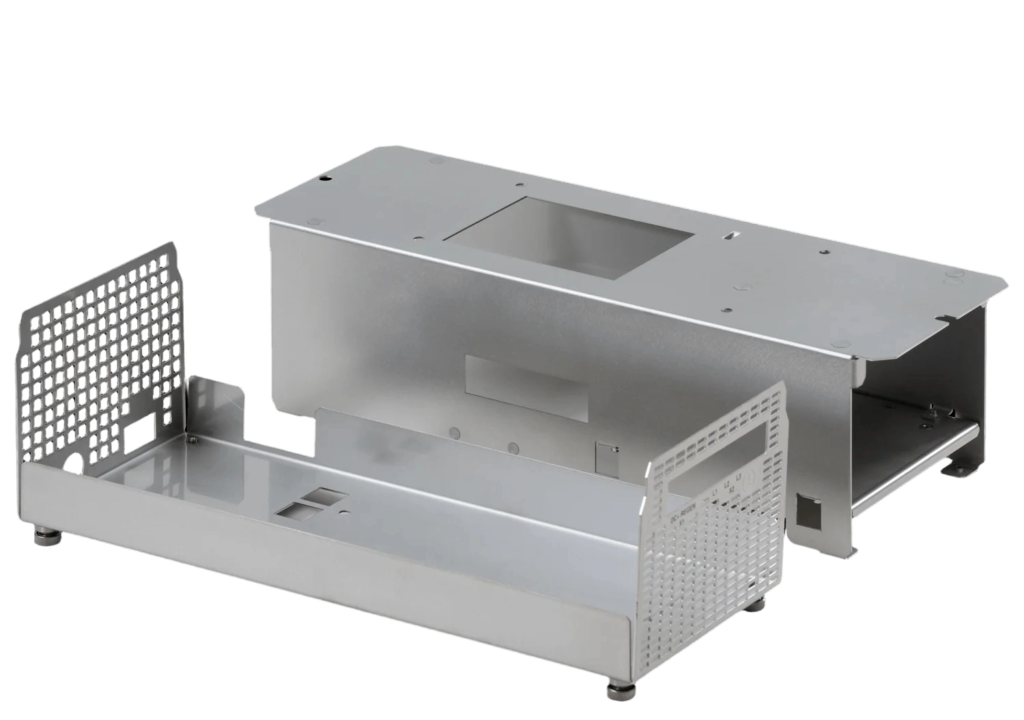

PremFixer is your premier partner for reliable, end-to-end sheet metal fabrication. Our facility is equipped with over 20 sets of advanced machinery, including high-precision CNC laser cutters, hydraulic bending machines, stamping presses, and professional welding stations. We offer the scalability to handle everything from low-volume rapid prototypes to high-volume production runs. With an in-house team of expert engineers, we ensure every component is manufactured to rigorous tolerances and global quality standards.

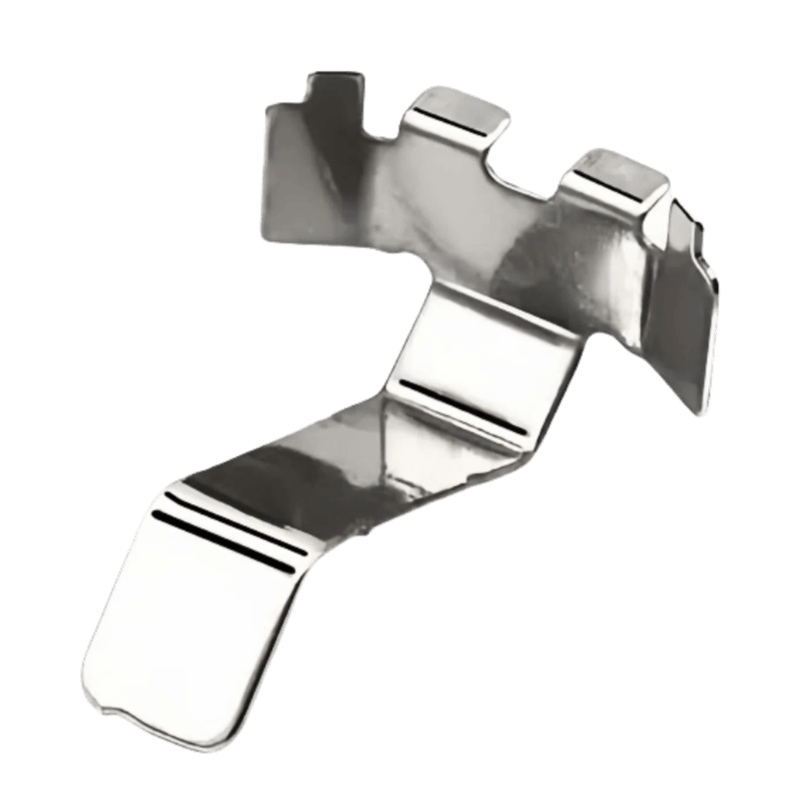

Metal Stamping

Precision Metal Stamping utilizes high-tonnage presses and custom dies to shape sheet metal with extreme efficiency. It is the ideal solution for mass-producing uniform parts with complex geometries, offering high repeatability and significant cost-effectiveness for large-scale industrial runs.

Welding

Industrial Welding ensures structural integrity by fusing materials at the molecular level. PremFixer specializes in high-strength MIG, TIG, and Arc welding methods, often utilizing premium filler materials to create seamless, leak-proof joints for mission-critical assemblies in aerospace and energy sectors.

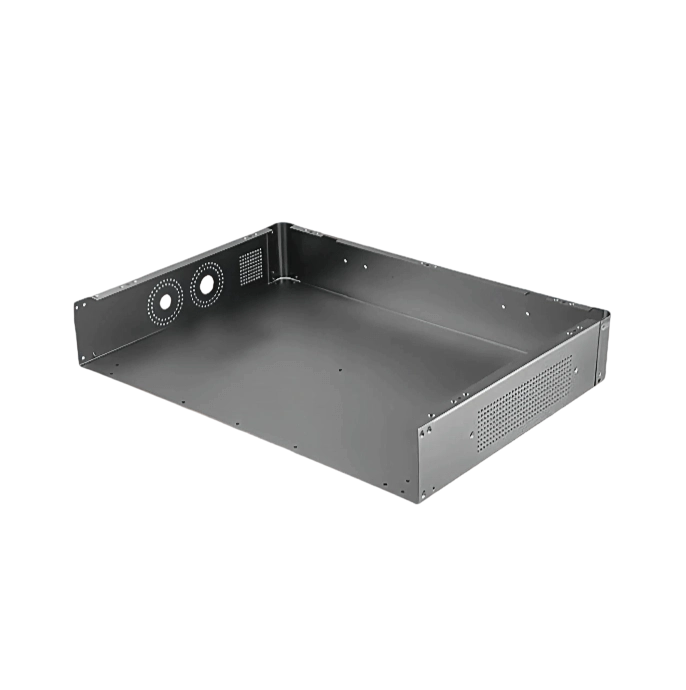

CNC Laser Cutting

CNC Laser Cutting leverages high-power focused beams to melt or vaporize material with surgical precision. This process delivers ultra-clean edges and tight tolerances without the need for expensive tooling, making it perfect for rapid prototyping and intricate designs in stainless steel, aluminum, and carbon steel.

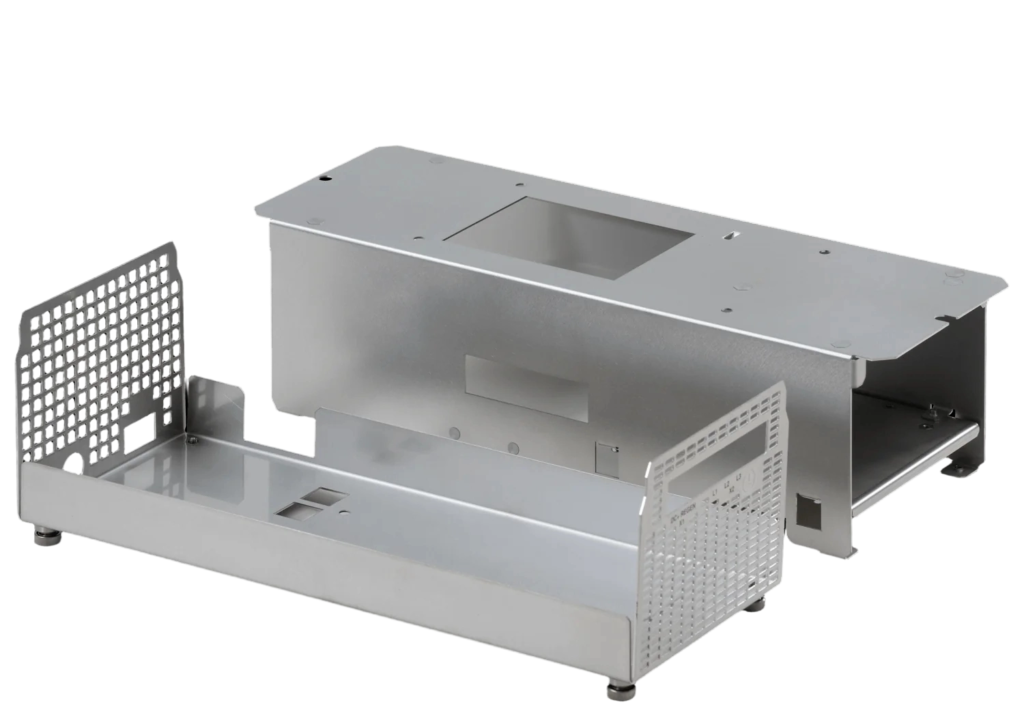

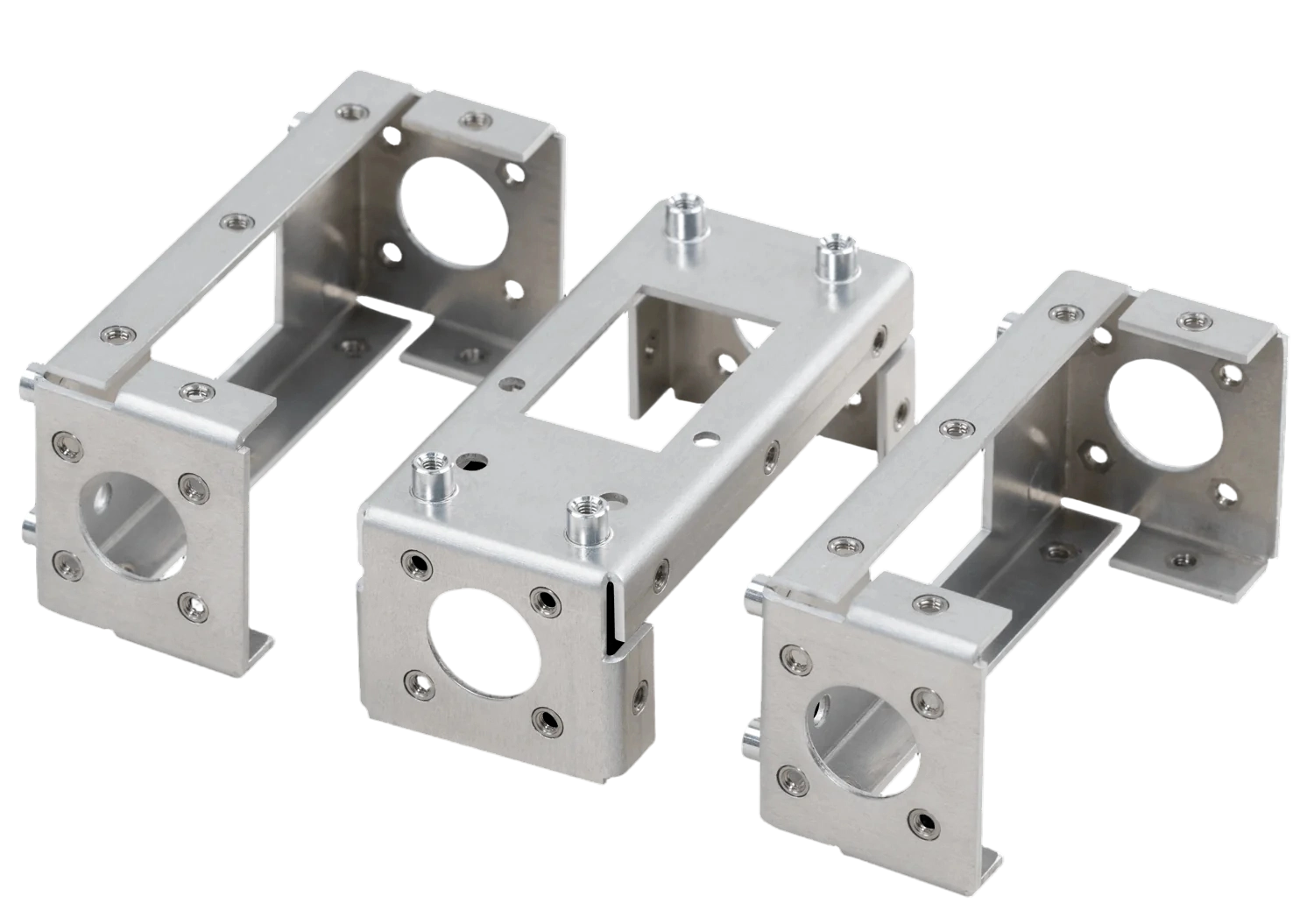

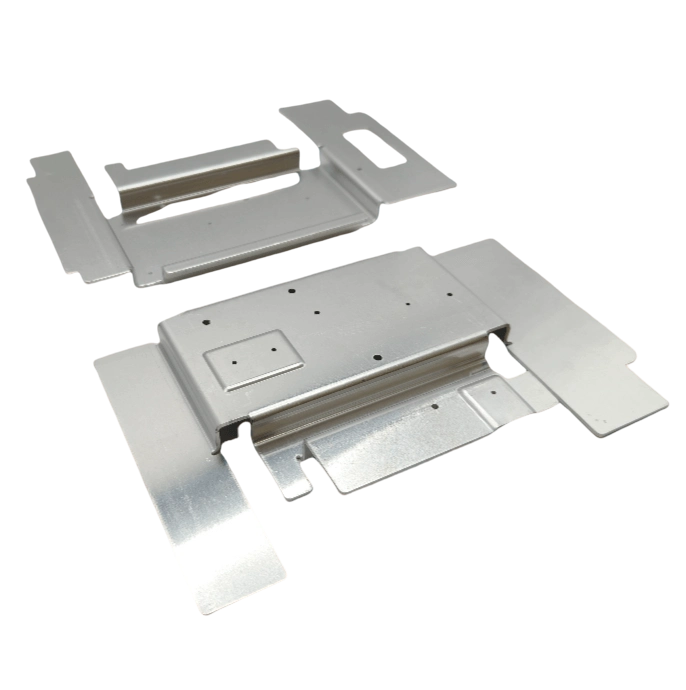

CNC Bending & Forming

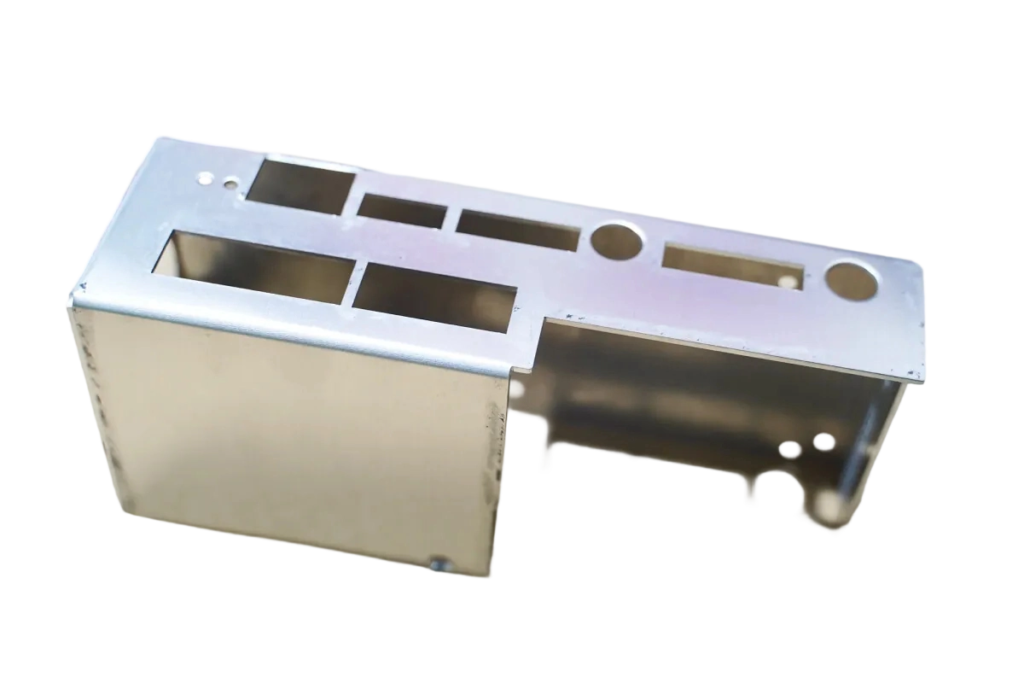

Our CNC Bending services utilize advanced press brakes to deform sheet metal into precise angles and multi-dimensional shapes. By controlling the bending pressure and position with computer precision, we ensure high repeatability and dimensional accuracy for everything from simple brackets to complex enclosures.

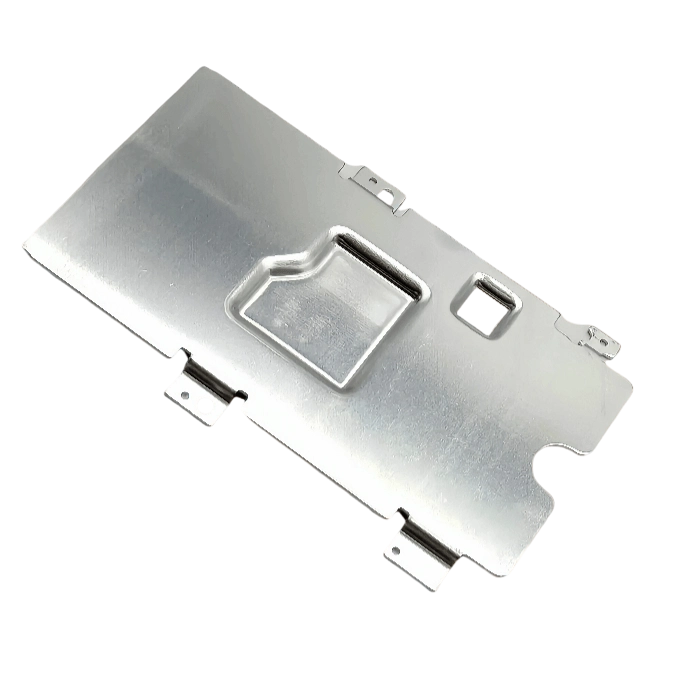

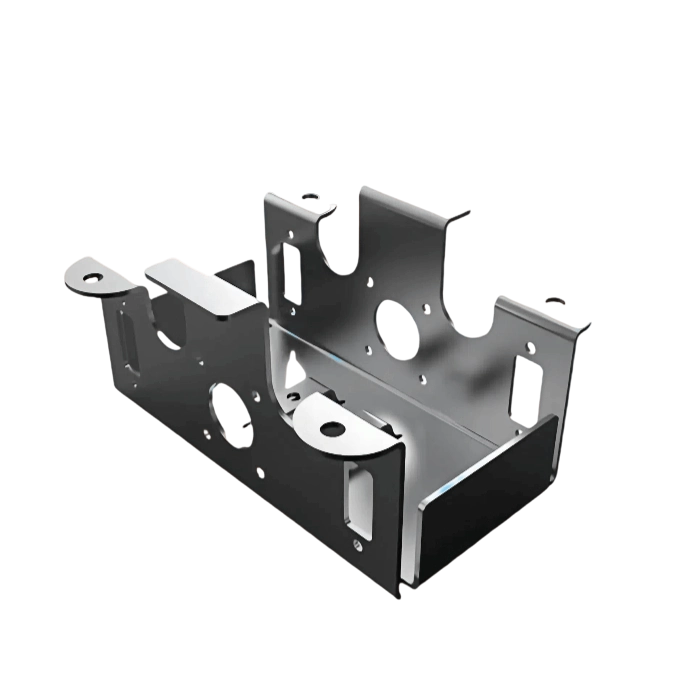

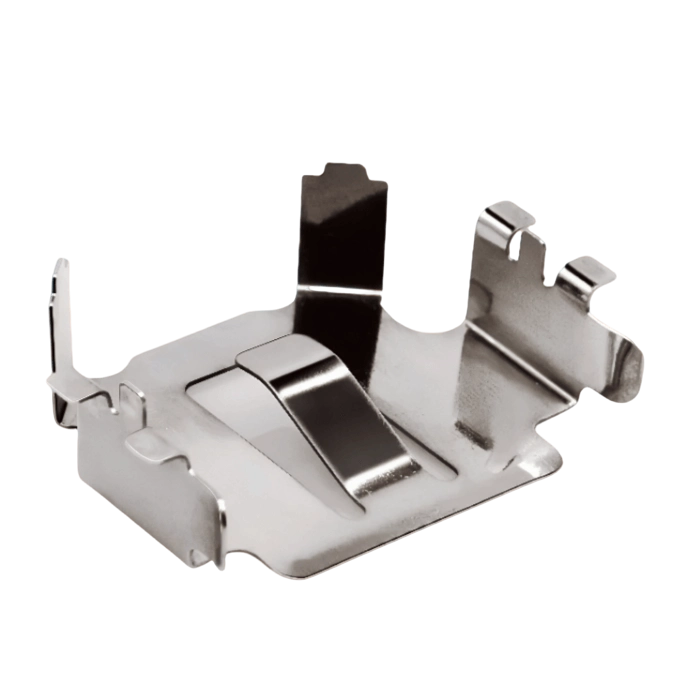

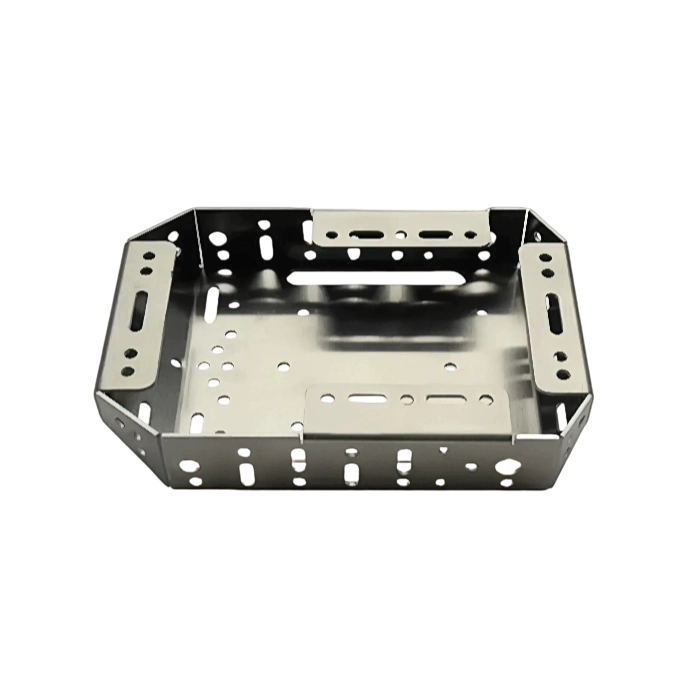

All Type Sheet Metal Fabrication Parts We Made

Sheet Metal Materials & Professional Surface Finishing

Precision sheet metal fabrication is a cornerstone of modern manufacturing, offering the versatility and efficiency required for high-performance industrial applications. At PremFixer, our advanced processes allow us to produce complex metal components with tight tolerances and consistent, repeatable quality. From material selection to final coating, we provide a seamless, integrated solution for all your custom metal needs.

Surface Finishing

16+ Premium Surface Finishes for Custom Sheet Metal Parts

Elevate the durability and aesthetic appeal of your components with PremFixer’s extensive range of surface treatment solutions. From anodizing and powder coating to bead blasting, we deliver high-quality finishes tailored to your functional and decorative needs—in as fast as 7 days. Every design deserves professional-grade protection; choose the perfect texture, color, and performance level to step up your project quality today.

Guide to Selecting Sheet Metal Materials & Finishes

At PremFixer, we help you navigate the selection process using these 7 key technical factors:

- Mechanical Properties: Evaluate tensile strength, ductility, and Rockwell hardness to meet the application’s physical stress requirements.

- Alloy Specification: Select the ideal grade (e.g., Aluminum 6061, 304 Stainless, or C110 Copper) based on specific material characteristics.

- Gauge & Thickness: Determine the optimal thickness to balance structural integrity with bending formability.

- Environmental Resilience: Assess the need for corrosion resistance (e.g., selecting 316 Stainless for marine or harsh environments).

- Fabrication Compatibility: Ensure the material is optimized for precision laser cutting, CNC bending, and welding.

- Cost Optimization: Balance material availability and processing expenses to maximize your manufacturing budget.

- Strength-to-Weight Ratio: Prioritize lightweight materials like aluminum for aerospace or automotive applications where mass reduction is critical.

Precision Sheet Metal Fabrication Capabilities

| Description | Standard |

|---|---|

| General Tolerances | Metals : ISO 2768-c |

| Cutting Feature | ± .0078″ / 0.2mm |

| Bend Angle | ± 1.0° |

| Bend to Edge | ±0.010″ / 0.254mm |

| Bend to Hole | ±0.2 mm |

How To Work With Us

In order to saving the time and cost for our customer, we simply the working process, from the prototypes to custom parts deliveried fast only with 4 simple steps.

Send Us Design

Click any quote button on our website, fill in your requirements and upload the drawings.

Quote Analysis

Our engineers will analyze how to improve the parts and then provide you with the best prices.

Order Confirmed

After you confirm the quote, samples will be sent for approval, then bulk will be made.

Get your Goods

Custom precision parts undergo our QC inspection with flexible shipping via sea, air, or rail.

Get Your Custom Surface Finishing Today!

China-Based Manufacturer: Fasteners & Precision Custom Parts

Accelerate your project timeline with PremFixer’s precision CNC and fabrication services. We specialize in translating complex ideas into high-performance hardware with industry-leading lead times. From one-off prototypes to scalable production runs, we provide the technical expertise and quality assurance needed to drive your innovation forward. [Get an Instant Quote]

Contact us today for a free quote or to discuss your project. Let’s work together to make your custom surface finishing precise, durable, and cost-effective.