🔔From Engineer to Branded Customized Customer. Quality Parts. Fast. Easy. Affordable.g

📧

kyrie@premfixer.com

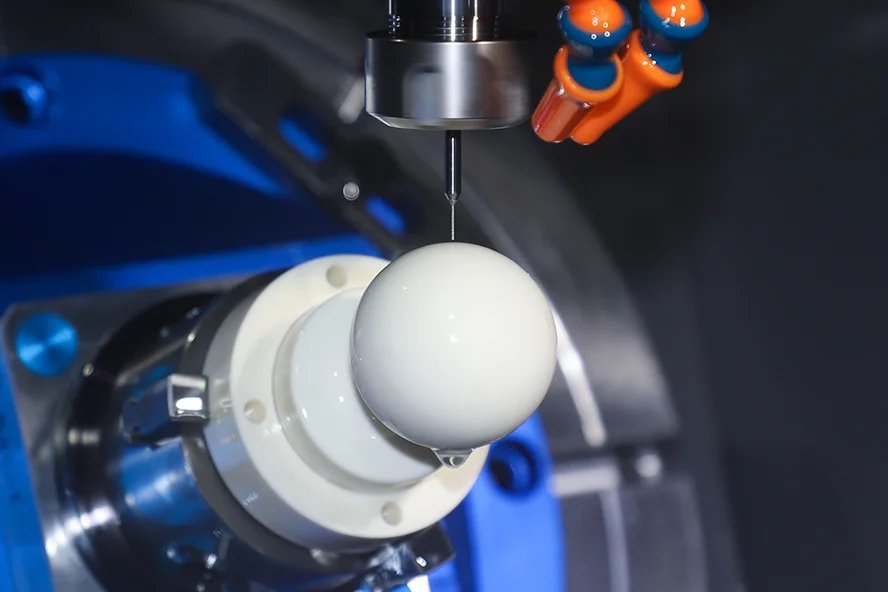

Custom Ceramic CNC Machining Services

We deliver technical-grade ceramic components machined to exacting standards, combining advanced CNC technology with specialized expertise to meet your most demanding specifications for accuracy, surface finish, and reliability.

- Material Certificates

- Save 30% vs. Local Suppliers

- Fast Turnaround

- 15+ Years Experience

We solemnly guarantee

: All uploads files are safe and confidentia

What’s Ceramic CNC Machining?

Ceramic CNC machining is a specialized manufacturing process that utilizes computer-controlled equipment to shape and finish high-performance ceramic materials with exceptional precision.

As a highly effective manufacturing solution, ceramic CNC machining enables the production of intricate, durable parts critical to various high-tech industries. Its capability to achieve complex geometries and superior durability makes it indispensable, even considering the challenges posed by the inherent brittleness and hardness of ceramics.

At Prem Fixer, we provide professional ceramic CNC machining services, manufacturing high-quality components characterized by tight tolerances and complex geometries to meet your most demanding specifications.

Common Types of Ceramics

Hardness

Ceramics are generally harder than metals, making them suitable for wear-resistant applications.

Brittleness

While they are strong, ceramics are also brittle, which means they can crack or chip under stress.

Thermal Stability

They can withstand high temperatures without losing structural integrity.

Chemical Resistance

Ceramics are resistant to many corrosive substances, making them ideal for harsh environments.

Common Engineering Ceramics

Various advanced ceramics possess unique mechanical, thermal, and electrical properties, making them critical for demanding applications across high-performance industries such as aerospace, medical, electronics, and precision manufacturing. Understanding the specific characteristics and optimal uses of each material is essential for selecting the most suitable ceramic to meet rigorous engineering and manufacturing requirements.

Properties:

- High hardness and wear resistance.

- Excellent electrical insulator.

- Good chemical stability and corrosion resistance.

- High melting point (around 2050°C or 3722°F).

Applications:

- Used in cutting tools, wear-resistant parts, and insulators.

- Common in medical devices (e.g., dental implants, prosthetics).

- Employed in electrical components and substrates.

Properties:

- Exceptional toughness and strength.

- Good thermal insulation properties.

- Can be partially stabilized to improve performance.

- High resistance to wear and corrosion.

Applications:

- Widely used in dental applications for crowns and bridges.

- Employed in fuel cell components and thermal barrier coatings.

- Used in cutting tools and industrial applications.

Properties:

- Extremely hard and wear-resistant.

- High thermal conductivity and low thermal expansion.

- Excellent chemical stability.

- Capable of withstanding high temperatures.

Applications:

- Used in abrasive materials, grinding wheels, and cutting tools.

- Employed in high-performance ceramics for aerospace and automotive applications.

- Common in electronic devices, such as semiconductor substrates.

Properties:

- Excellent thermal conductor, effective for heat dissipation.

- High electrical resistivity, making it an effective insulator while maintaining thermal conductivity.

- Resistant to oxidation and stable across a wide range of temperatures.

- Comparable to diamond, making it suitable for cutting and grinding applications.

Applications:

- Used as an insulating substrate in electronic devices and components.

- Employed as a material for cutting tools and abrasives due to its hardness.

- Used as a solid lubricant in high-temperature applications.

- Applied as a protective coating to enhance wear resistance and reduce friction in mechanical parts.

Properties:

- Excellent ability to conduct heat, making it effective for thermal management applications.

- High electrical resistivity allows it to serve as an effective insulator while conducting heat.

- Resistant to oxidation and stable in harsh chemical environments, enhancing durability.

- Exhibits low friction properties, making it suitable for use as a lubricant in various applications.

Applications:

- Used as insulating substrates and components in electronic devices due to its electrical insulation properties.

- Employed in high-performance cutting tools and abrasives, leveraging its hardness and thermal stability.

- Used in heat sinks and thermal interface materials to improve heat dissipation in electronic systems.

- Applied as protective coatings in mechanical systems to reduce wear and friction.

Properties:

- Can withstand temperatures up to 1,000°C (1,832°F) without losing its mechanical integrity.

- Can be easily machined using conventional tools, allowing for precise shaping and finishing.

- Provides excellent electrical insulation properties, making it suitable for electrical applications.

- Resistant to many chemicals and solvents, which enhances its durability in various environments.

Applications:

- Commonly used in high-voltage electrical applications and as insulators in electronic devices.

- Used in components that require high-temperature stability and insulation, such as thermal barriers.

- Employed in the fabrication of parts that need to withstand harsh chemical environments.

- Utilized for custom fixtures and tooling due to its machinability and stability.

Advantages of CNC Machining Ceramic

How To Work With Us

In order to saving the time and cost for our customer, we simply the working process, from the prototypes to custom parts deliveried fast only with 4 simple steps.

Send Us Design

Click any quote button on our website, fill in your requirements and upload the drawings.

Quote Analysis

Our engineers will analyze how to improve the parts and then provide you with the best prices.

Order Confirmed

After you confirm the quote, samples will be sent for approval, then bulk will be made.

Get your Goods

Custom precision parts undergo our QC inspection with flexible shipping via sea, air, or rail.

Get Your Custom Ceramic Machining Parts Today!

From initial concept to full-scale production, PremFixer is dedicated to providing precision-engineered solutions with an accelerated time-to-market. Whether your project requires low-volume custom parts, rapid prototyping, or complex high-precision components for mission-critical hardware, our expert engineering team delivers the accuracy and reliability your industry demands.

Contact us today for a free quote or to discuss your project. Let’s work together to make your metal parts precise, durable, and cost-effective.