🔔From Engineer to Branded Customized Customer. Quality Parts. Fast. Easy. Affordable.g

📧

kyrie@premfixer.com

Kovar Alloy CNC Machining

Kovar Alloy is utilized in a variety of specialized applications due to its unique properties, particularly its low coefficient of thermal expansion and mechanical stability.

- Material Certificates

- Save 30% vs. Local Suppliers

- Fast Turnaround

- 15+ Years Experience

We solemnly guarantee

: All uploads files are safe and confidentia

Custom Kovar Alloy CNC Machining Services in China

Are you looking for a reliable, quick-turn supplier of Kovar Alloy CNC machining parts?

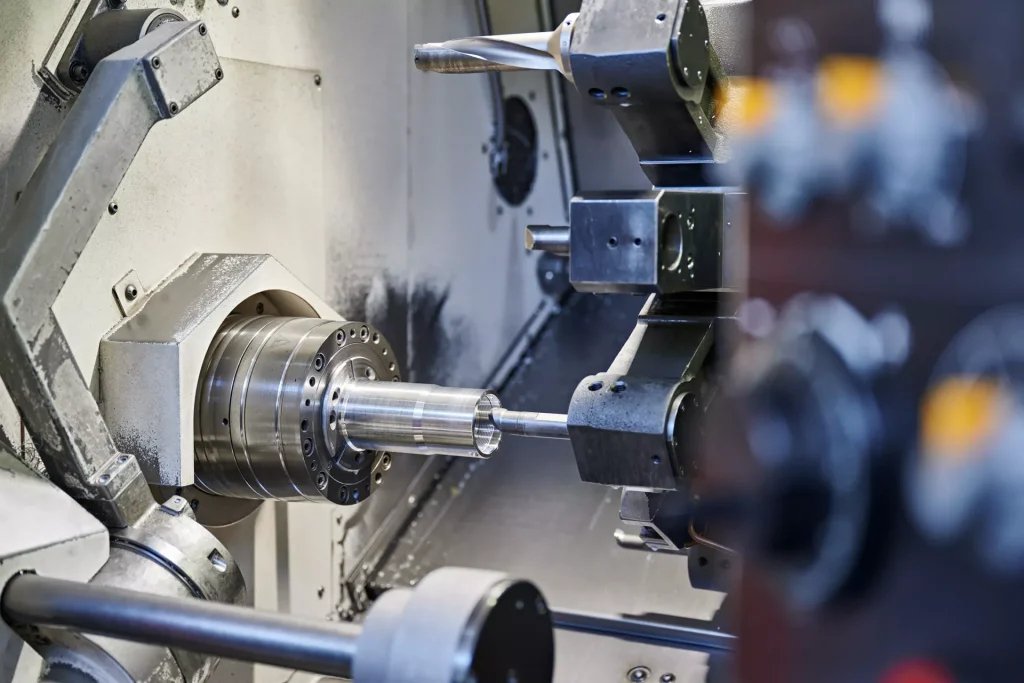

PremFixer is your reliable manufacturing partner in China for controlled expansion alloys. We specialize in CNC machining Kovar parts that require tight tolerances and stable performance in aerospace and telecommunications. With over 15 years of experience in Kovar turning and milling, we ensure your parts maintain perfect thermal expansion matching with glass and ceramics—delivered with fast lead times and competitive pricing.

What’s Kovar Alloy?

Precision Kovar Alloy CNC Machining | ASTM F15 Solutions

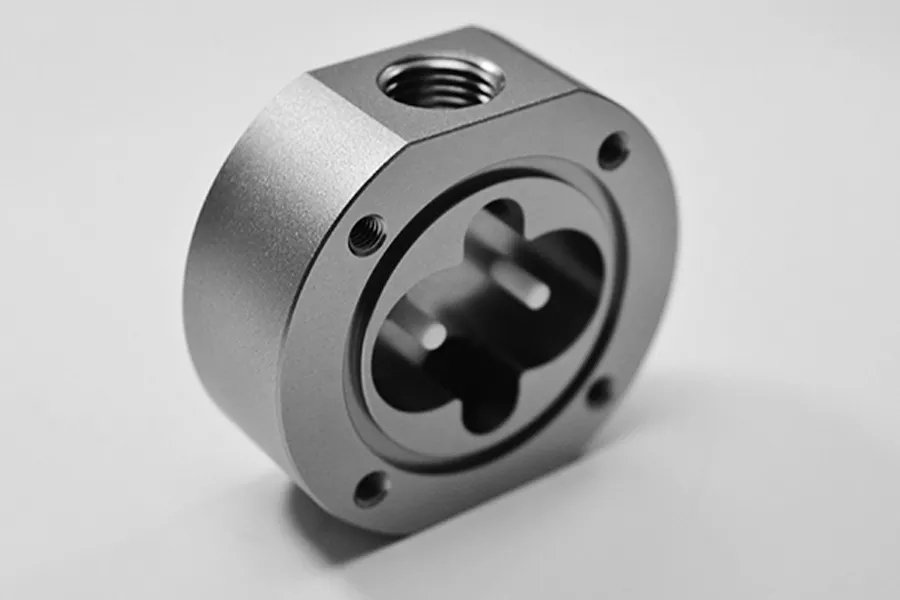

Kovar (ASTM F15) is a specialized nickel-cobalt ferrous alloy composed of 29% Nickel, 17% Cobalt, and 54% Iron. Renowned for its controlled low thermal expansion (CTE), Kovar is the industry standard for applications requiring seamless compatibility with hard glass and ceramics.

While CNC machining Kovar alloy presents unique challenges due to its toughness, its exceptional dimensional stability makes it indispensable for electronics, aerospace, and telecommunications. At PremFixer, we leverage advanced tooling and decades of expertise to produce high-precision Kovar parts with tight tolerances and complex geometries, ensuring perfect hermetic sealing for your mission-critical components.

Material Properties of Superalloy

Low CTE

Closely matches that of glass and ceramics, minimizing thermal stress in sealing applications.

Mechanical Strength

Offers good tensile and yield strength, providing stability and durability under mechanical stress.

Magnetic Properties

It can be magnetized. This is important in applications that require the alloy to interact with magnetic fields.

Weldability

Can be effectively welded to many materials, allowing for versatile assembly in electronic packaging.

Industrial Applications of Kovar (ASTM F15) Alloy

Across the Aerospace, Telecommunications, and Defense sectors, Kovar is indispensable. Its unique combination of dimensional stability and magnetic shielding makes it a versatile solution for sensitive electronic housings and vacuum components. PremFixer’s expert Kovar CNC machining ensures that these properties are preserved, providing you with high-strength, weldable parts that perform flawlessly under extreme thermal stress.

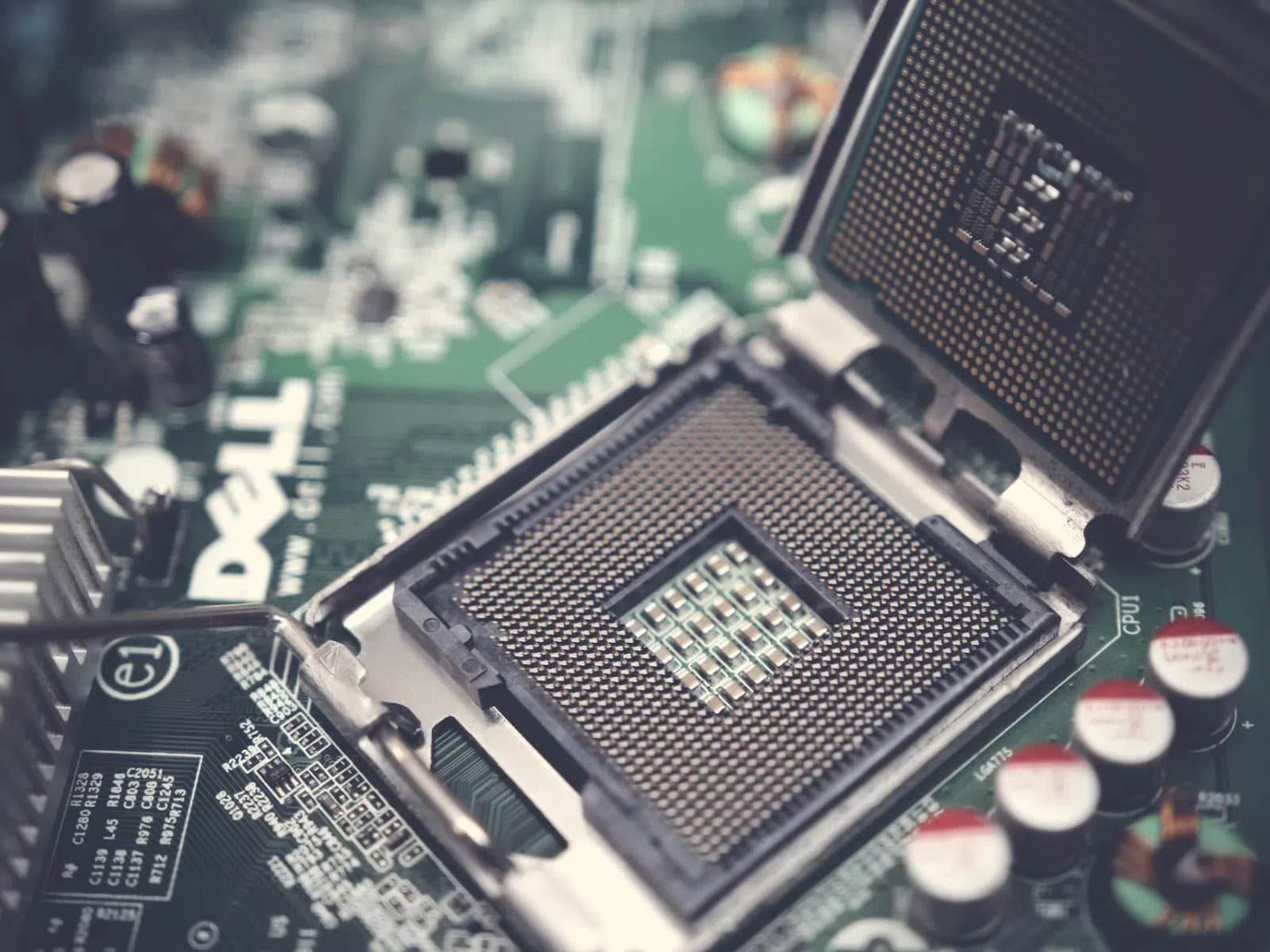

Electronic Packaging

Used for glass-to-metal seals in vacuum tubes, transistors, and semiconductor packages.

Aerospace

Utilized in sealing components and housings for satellites and spacecraft.

Sensors and Actuators

Used in precision sensors and actuator components requiring stability and accuracy.

Telecommunications

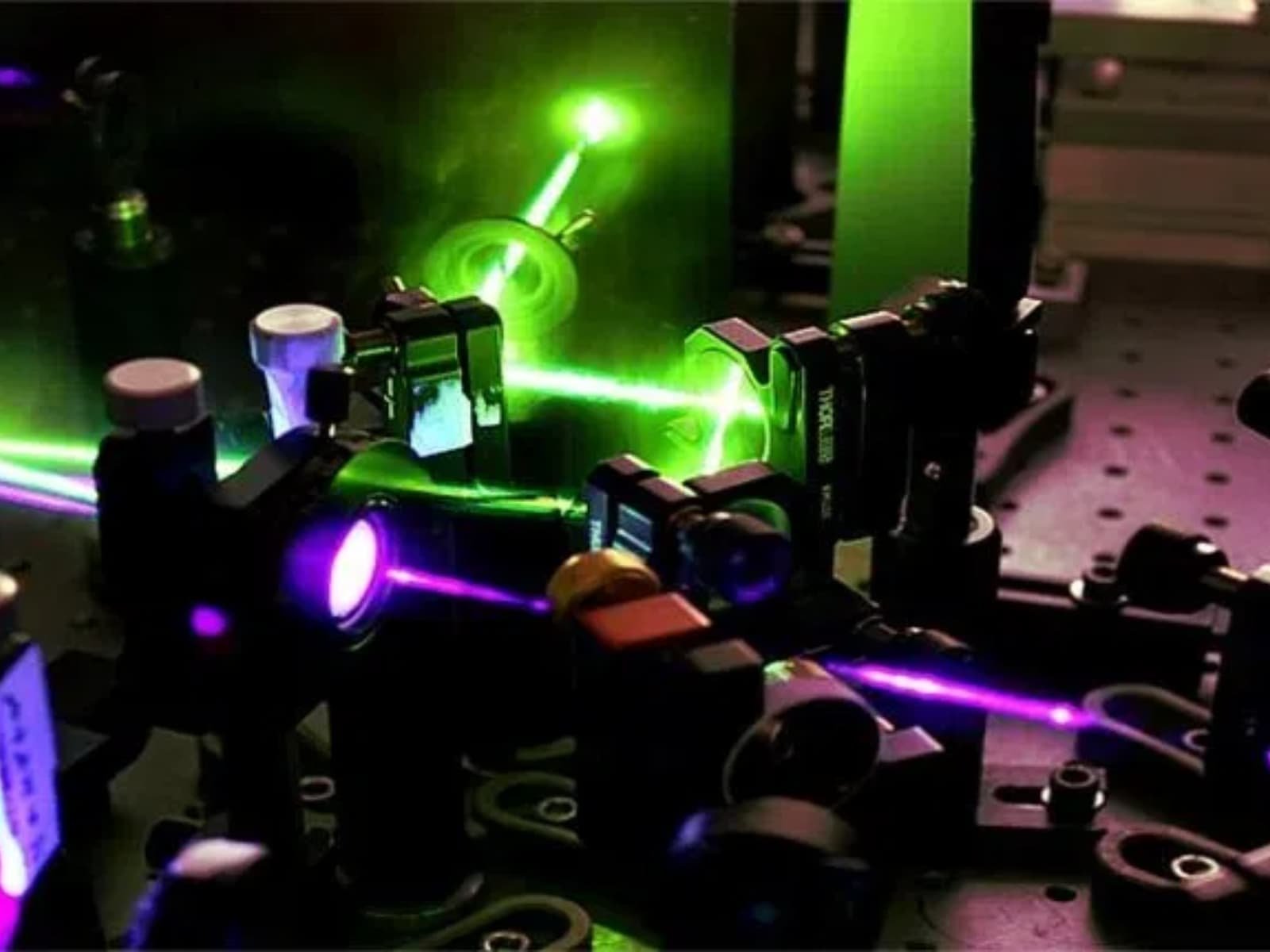

Applied in high-performance electronics, including RF and microwave component packaging.

Medical Devices

Employed in implants and surgical instruments due to its biocompatibility.

Optoelectronics

Commonly used for packaging laser diodes and LED components to ensure thermal stability.

What’s the Challenges in Kovar CNC Machining?

Kovar alloy is a cornerstone of modern engineering due to its controlled thermal expansion and superior dimensional stability. At PremFixer, we leverage Kovar’s excellent weldability and high mechanical strength to manufacture components for the most demanding environments. From precision magnetic shielding to high-vacuum hardware, our Kovar CNC machining services provide the reliability required for mission-critical industrial applications.”

How To Work With Us

In order to saving the time and cost for our customer, we simply the working process, from the prototypes to custom parts deliveried fast only with 4 simple steps.

Send Us Design

Click any quote button on our website, fill in your requirements and upload the drawings.

Quote Analysis

Our engineers will analyze how to improve the parts and then provide you with the best prices.

Order Confirmed

After you confirm the quote, samples will be sent for approval, then bulk will be made.

Get your Goods

Custom precision parts undergo our QC inspection with flexible shipping via sea, air, or rail.

Get Your Custom Kovar Alloy Parts Today!

From initial design concept to final product delivery, PremFixer is committed to providing exceptional quality and rapid turnaround times. Whether you require low-volume custom parts, rapid prototyping, or high-precision components for mission-critical applications, our expert engineering team is ready to scale with your project. Experience the reliability of a world-class CNC machining partner.

Contact us today for a free quote or to discuss your project. Let’s work together to make your metal parts precise, durable, and cost-effective.