🔔From Engineer to Branded Customized Customer. Quality Parts. Fast. Easy. Affordable.g

📧

kyrie@premfixer.com

Quick-Turn Prototyping and Scalable Production for Motorcycle & Bicycle Hardware

As a specialized manufacturer of CNC machined aluminium motorcycle and bicycle components, we offer extensive precision prototyping and production experience. Our parts are trusted by global custom motorcycle and bicycle brands for their accuracy, performance, and reliability.

- Tight Tolerances: ±0.005mm

- Fast Turnaround from 3 – 20 days

- 20+ Surface Finishes Options

- 50+ Metals & Plastic Materials For Choose

We solemnly guarantee

: All uploads files are safe and confidentia

CERTIFICATIONS :ISO 9001:2015

Trusted by

Why Rapid Manufacturing Matters for Motorcycle & Bicycle Components

Prototyping and rapid manufacturing play a critical role in the development of motorcycles and bicycles for several key reasons.

Design Validation & Safety: Prototyping allows for rigorous testing of fastener integrity and accessory fitment, ensuring every critical component performs safely under extreme road conditions before mass production.

Cost & Time Efficiency: Rapid prototyping accelerates the design cycle and eliminates expensive rework. By avoiding traditional tooling costs during the iterative stage, we significantly shorten your time-to-market.

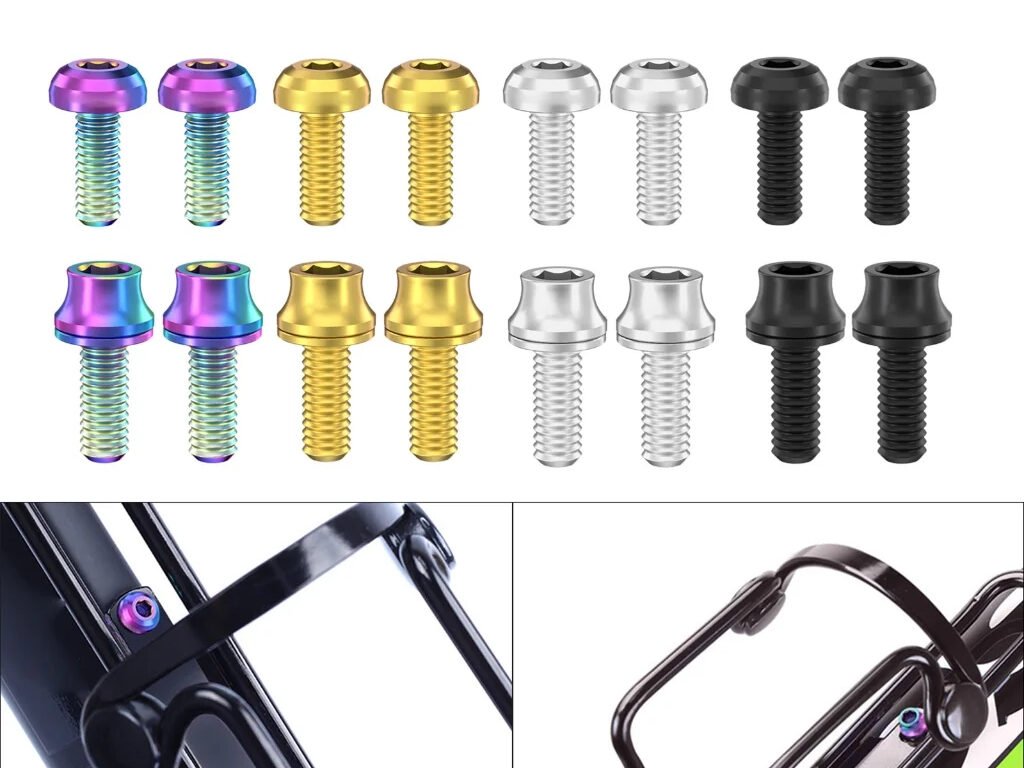

Customization and Personalization: We provide tailored solutions for ergonomics and lightweight performance, enabling the development of high-strength, precision-engineered fasteners and accessories for niche racing and consumer markets.

Risk Mitigation: Early detection of structural flaws prevents costly production errors and recalls, ensuring that your mission-critical fasteners meet the highest industry reliability standards.

Applications of CNC Machining in the Motorcycle & Bicycle Industry

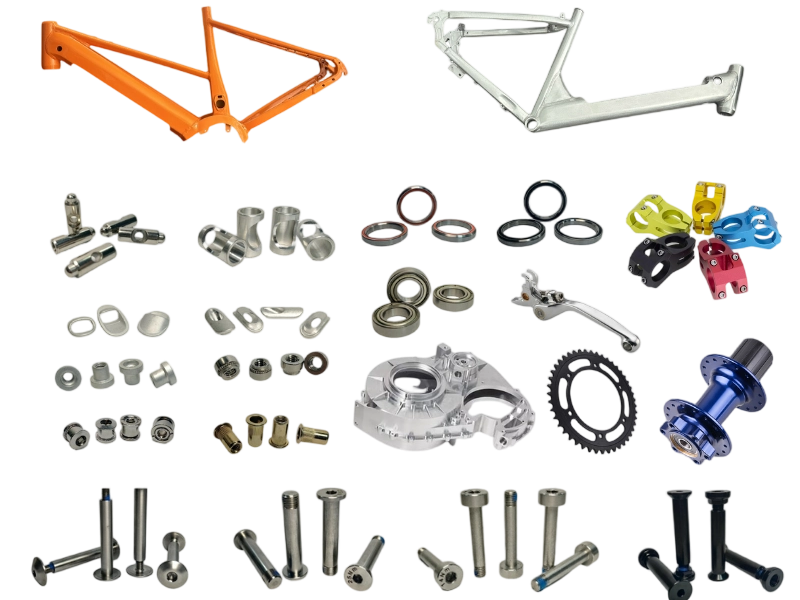

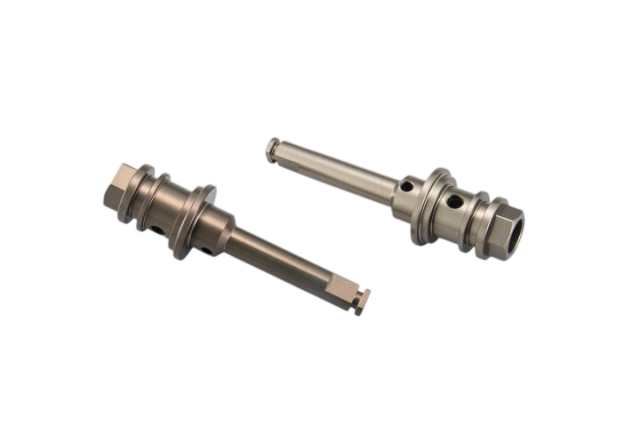

CNC machining and rapid manufacturing are the gold standards for producing high-performance motorcycle and bicycle components. These technologies are essential for parts that demand extreme precision, superior durability, and optimized strength-to-weight ratios. At PremFixer, we utilize advanced CNC techniques to deliver mission-critical components, including:

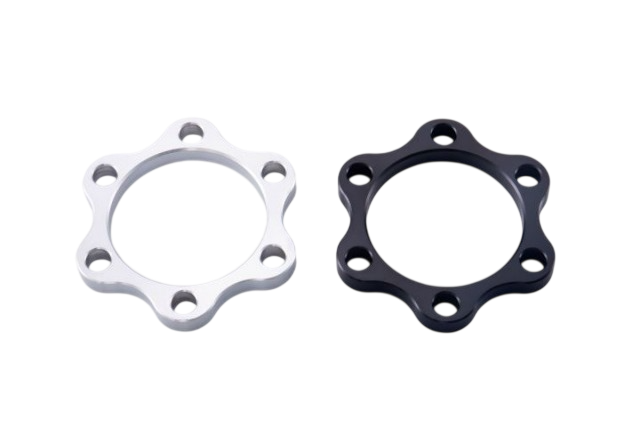

Bicycle Fastener Solutions

Aluminum and Carbon Fiber Frame Components

Cylinder Heads and Cylinders

Aluminum alloy and carbon fiber frame

Chainrings and Cassettes

Brake Levers and Calipers

Excellent machining Parts We Made

How To Work With Us

Streamlined Manufacturing Process in 4 Simple Steps. To save you time and cost, PremFixer has simplified the entire workflow. From rapid prototyping to the final delivery of custom parts, we ensure a seamless experience that accelerates your time-to-market.

Send Us Design

Click any quote button on our website, fill in your requirements and upload the drawings.

Quote Analysis

Our engineers will analyze how to improve the parts and then provide you with the best prices.

Order Confirmed

After you confirm the quote, samples will be sent for approval, then bulk will be made.

Get your Goods

Custom precision parts undergo our QC inspection with flexible shipping via sea, air, or rail.