🔔From Engineer to Branded Customized Customer. Quality Parts. Fast. Easy. Affordable.g

📧

kyrie@premfixer.com

Custom Surface Finishing Services

PremFixer provides 20+ types of surface finishes to make your on-demand plastic and metal parts to be more corrosion-resistant or get a specific look.

- 20+ Finishes Choose

- Save 30% vs. Local Suppliers

- Fast Turnaround

We solemnly guarantee

: All uploads files are safe and confidentia

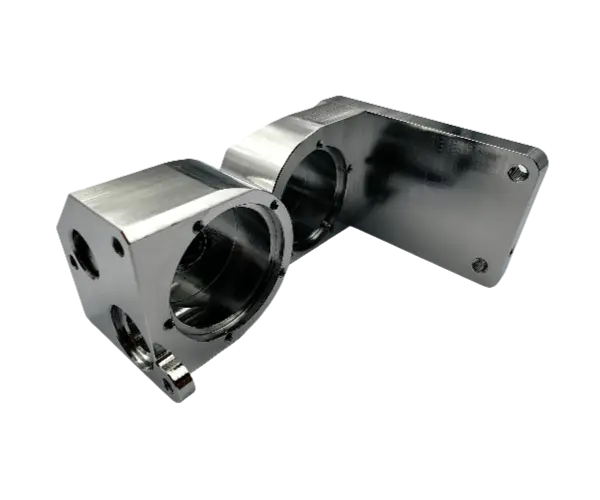

CNC machining Materials We Offer

Surface Finishes & Post-Processing Services. In precision manufacturing, surface finish defines the texture, smoothness, and durability of a part after machining. Beyond aesthetics, the right surface treatment is critical for improving wear resistance, reducing friction, and ensuring corrosion protection in harsh environments.

At PremFixer, we offer a comprehensive range of standard and custom surface finishes tailored to your project’s needs. From “as-machined” smoothness to cosmetic polishing and anodizing, explore the finishing options we commonly apply:

| Image | Finishing | Description | Application |

|---|---|---|---|

|

As-Machined | Standard Cost-Effective CNC Surface Finish. The raw surface directly produced by CNC machining processes, maintaining tight dimensional tolerances while retaining visible tool marks. This CNC machining finish is ideal for internal functional components where performance is prioritized over aesthetics. Roughness: Ra 1.6-3.2 μm (63-125 μin). |

Prototypes, functional parts where aesthetics aren’t critical. |

|

Smooth | Reduced Roughness CNC Surface Finish. A mechanical smoothing process for CNC machined parts that eliminates minor tool marks and reduces surface friction. This smooth CNC finish delivers improved sealing surfaces and tighter assembly fits compared to standard CNC machining finishes. Roughness: Ra 0.4-0.8 μm (16-32 μin). |

Used for parts that need a refined appearance or smoother contact surfaces such as consumer goods, medical components, and medical devices. |

|

Bead Blasting | Uniform Matte CNC Surface Finish. High-pressure glass bead spray treatment for CNC machined components removes tool marks and creates a consistent, non-reflective satin finish. This CNC bead blasting finish is excellent for cosmetic parts and as a pre-treatment for anodizing aluminum CNC parts. Roughness: Ra 2.9-3.8 μm (Matte). |

Used to achieve an even texture for aesthetic purposes, typically on consumer products or decorative parts. |

|

Anodizing | Corrosion Resistant CNC Anodizing Finish. Electrochemical passivation (Type II & Type III Hardcoat) for aluminum CNC machined parts. This CNC anodizing process increases surface hardness, wear resistance, and heat dissipation, available in Clear, Black, Red, Blue, and Gold finishes. Roughness: Unchanged. |

Commonly used in aerospace, electronics, and construction industries for aluminum parts. |

|

Polishing | Mirror-Like Gloss CNC Polishing Finish. Mechanical polishing for CNC machined parts removes all surface imperfections to achieve maximum optical clarity and smoothness. This CNC polish finish reduces friction and prevents contaminant adhesion. Roughness: Ra < 0.1 μm (Mirror). |

Used for aesthetic parts, reflective surfaces, or parts requiring low friction. |

|

Powder Coating | Durable Protective CNC Powder Coating Finish. Electrostatic powder application cured under heat for CNC machined metal parts. This CNC powder coating finish offers superior impact and UV resistance compared to wet paint, available in all RAL colors and textures. Roughness: Smooth to Textured. |

Used in automotive, industrial equipment, consumer products, and outdoor applications. |

|

Brushing | Directional Satin CNC Brushing Finish. Abrasive belts create a unidirectional grain pattern on CNC machined metal surfaces. This CNC brushing finish is ideal for decorative metal parts, effectively hiding fingerprints and minor surface defects on stainless steel and aluminum CNC components. Roughness: Ra 0.4-2.5 μm. |

Common in decorative and aesthetic applications, especially for stainless steel or aluminum products. |

|

Electroplating | Metal Deposition CNC Electroplating Finish (Zinc/Nickel/Chrome). Enhances corrosion resistance, hardness, and electrical conductivity of CNC machined parts. This CNC electroplating finish provides a shiny, metallic surface suitable for both decorative and functional CNC components. Roughness: Ra 2.9-3.8 μm. |

Used to achieve an even texture for aesthetic purposes, typically on consumer products or decorative parts. |

|

Passivation | Stainless Steel CNC Passivation Finish. Chemical removal of free iron and contaminants from CNC machined stainless steel parts to prevent rust. This CNC passivation process enhances natural corrosion resistance without altering part dimensions. Roughness: Unchanged. |

Commonly used in medical, food processing, and aerospace industries where corrosion resistance is critical. |

|

Heat Treating | Hardening & Tempering CNC Heat Treatment Finish. Thermal processing for CNC machined structural components (Annealing, Case Hardening). This CNC heat treating process increases material strength, hardness (HRC), and wear resistance for high-performance CNC parts. Roughness: May require post-grinding. |

Used for parts that need wear resistance or improved mechanical properties, like gears and cutting tools. |

|

Electropolishing | Micro-Smoothing CNC Electropolishing Finish. An electrochemical “reverse plating” process for CNC machined parts that removes surface peaks. This CNC electropolishing finish greatly improves corrosion resistance, passivity, and cleanability for sterile environment CNC components. Roughness: Ra < 0.2 μm (High Shine). |

Used in medical, pharmaceutical, and food processing equipment for cleanliness and corrosion resistance. |

|

Chromating | Chem Film / Alodine CNC Chromating Finish. A chemical conversion coating for aluminum CNC machined parts (Mil-DTL-5541). This CNC chromating finish provides excellent corrosion protection while maintaining electrical conductivity, serving as an ideal primer base. Roughness: Unchanged. |

Used in aerospace and electronics industries where corrosion resistance and conductivity are important. |

|

Sandblasting | Aggressive Surface Texturing CNC Sandblasting Finish. Uses silica or aluminum oxide media to remove rust and heavy contaminants from CNC machined surfaces. This CNC sandblasting finish creates a rougher texture than bead blasting, ideal for coating adhesion on CNC parts. Roughness: Ra 2.5-10 μm. |

Prepares surfaces for coating, removes old paint, or creates a rough texture for improved adhesion of coatings. |

|

Tumbling | Deburring & Smoothing CNC Tumbling Finish. A mass-finishing process for small to medium CNC machined parts using abrasive media in a rotating tumbler. This CNC tumbling finish removes burrs, sharp edges, and minor surface irregularities, creating a uniform matte texture on metal CNC components. Roughness: Ra 1.0-2.5 μm (Smooth Matte). |

Used for high-volume CNC machined parts like fasteners, small components, and hardware to improve handling safety and surface consistency. |

About Us

Get Your Custom Surface Finishing Today!

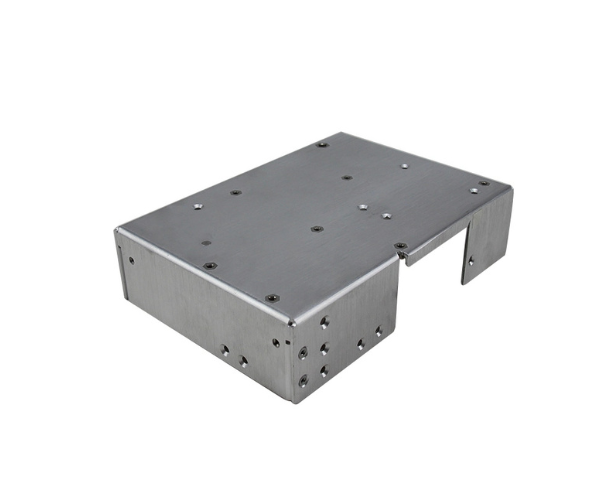

China-Based Manufacturer: Fasteners & Precision Custom Parts

“From Concept to Mass Production, PremFixer is committed to delivering ISO-certified quality and rapid turnaround on every order. Whether you require low-volume manufacturing, custom rapid prototyping, or high-precision CNC components for critical applications, our expert engineering team is ready to execute your design.”

Contact us today for a free quote or to discuss your project. Let’s work together to make your custom surface finishing precise, durable, and cost-effective.